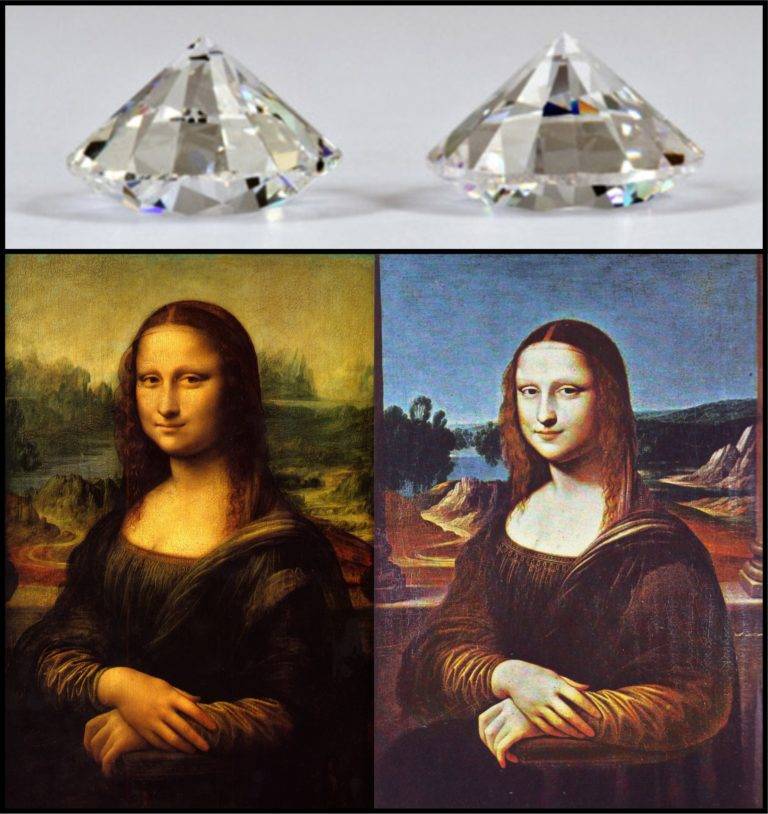

People have always prized “the real thing” over copies. This is why there is only one Mona Lisa. Extremely accurate copies can be made, but they are not prized nearly as highly as the priceless original. The idea that the copy is inferior to the original goes back at least as far as Plato’s “Republic”, where the ideas of “imitation” and “copy” are discussed in philosophical terms.

Other commonplace expressions convey this similar concept: we say “It’s the real McCoy” and “It’s the genuine article”.

But favoritism for originals is not an absolute rule: sometimes the copy is good enough. For those not willing to pay the price of a diamond, a cubic zirconia is a pretty close substitute. It’s flawless, colorless, and hard; just not quite as hard as a diamond and with a slightly lower refractive index (sparkle). For those willing to pay more than the price of a cubic zirconia, but still about one tenth the price of a diamond, moissanite is closer still. It is nearly as hard as diamond, and has an even higher refractive index. The ordinary person would not see the difference. But despite how close to the real thing these alternatives are, diamonds are far more expensive.

Another example is the difference between a “brand name” painkiller and its generic copy. In this case, the original and copy are even closer: they are chemically IDENTICAL. Yet, even so, people will still often pay more for “Tylenol” than for acetominophen.

In the decking world, a similar situation exists. Real wood is “the genuine article” and virtually all efforts to create a substitute decking material aim to create a material that has the look and texture of wood at its best.

Keeping it Real

While composite and artifical woods have numerous technical advantages, such as longevity, resistance to rot, and consistent grainless texture, in many cases people still want real wood. That preference comes with the need to handle and preserve the wood in ways that require more effort than what is needed for wood substitiutes.

In particular, genuine woods are more susceptible to dirt, moisture, warping, and rot. These drawbacks can however be largely offset with the appropriate effort, cleaners, brighteners, and stains. This is where Messmer products fit. Messmer makes a range of wood stains, finishes, and cleaners that go a long way to ensuring that the beauty of natural wood shows to its best and is preserved in the greatest measure possible.

Good choices in wood finishes can preserve or enhance the wood’s colour, reduce damage caused by ultraviolet rays from sunlight, offer resistance to mildew and rot, and seal woods against moisture.

Preserving and protecting woods involves considering a number of factors: the type of wood; its condition and age; whether the wood will be indoors or outdoors; whether the wood will be oriented vertically (as in fence slats) or horizontally (as in decking boards); how much foot traffic the wood needs to handle; and so on. These considerations will determine the specific wood treatment products used, and how often they might need to be reapplied: natural woods cannot be treated once and then forgotten, unless you are ready to sacrifice the benefits of nice-looking color and grain that drew you to select natural woods in the first place.

Messmer’s product line includes wood cleaners (a necessary detergent first stage for best staining results), wood brighteners (tannin extractors for woods prone to extractive bleeding) for enhancing grain and color in certain types of woods, and stains and finishes for indoor use, outdoor use, logs, and treatments that are targeted to specific types of woods. Cedar, redwood, and pine need one sort of product because of their open grain; teak, mahogany, meranti, and ipe need another because of their dense character. Pressure treated wood can also be stained, and again, the correct selection of treatment is needed.

As a general set of guidelines, wood should first be dry and clean and not coated with materials that would prevent stain penetrating deeply into the wood grain, such as paints, waxes, or silicones. If the wood is not new, it will need to be clean and dry; and pressure treated wood cannot be too freshly treated.

The goal is to have stains penetrate into the grain of the wood as far as possible. When staining, it’s important not to over-stain or insufficent penetration will occur, leading to blotches and shiny areas. Once the wood is saturated properly, any excess stain should be removed before it dries. Harder woods permit less stain penetration, and will need both lighter stain coats, and more frequent re-coating.

Once your natural wood is beautifully stained, you will need to maintain it with regular re-coating according to the wood type and weathering it receives.

If you are interested in going for the “real McCoy” and want to have natural wood decking and fencing, contact The Deck Store

Visit our website to find a location closest to you, or to contact a deck designer today!

Follow us on Facebook and Instagram for more deck design ideas.